U'amea lafo u'amea maualuga ma maualuga le ofuina tete'e

Faailoa atu

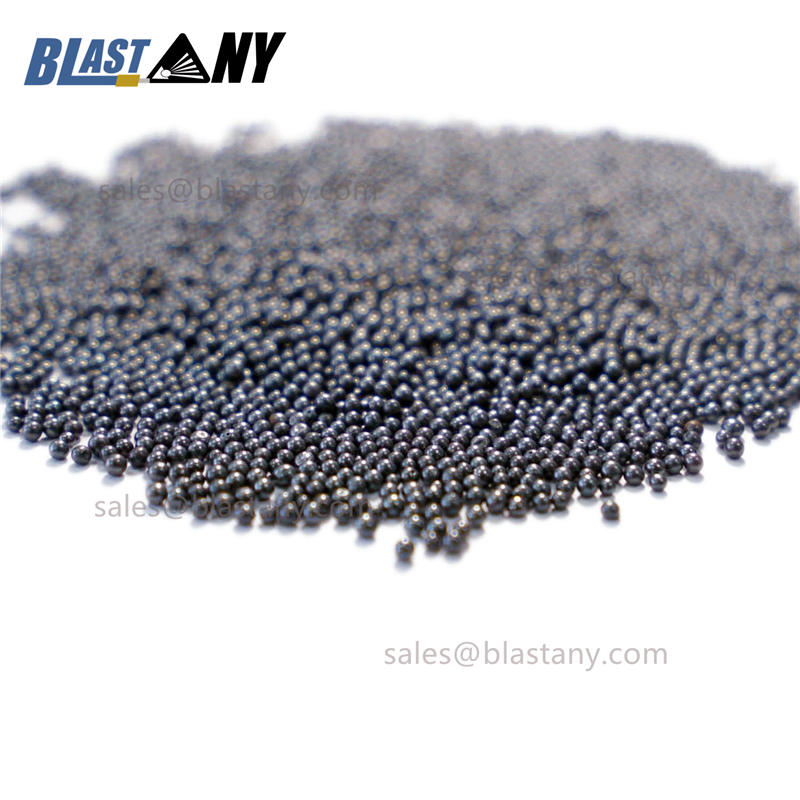

O le Junda Steel Shot e gaosia e ala i le liusuavai o fasi mea filifilia i totonu o le ogaumu eletise. O le vailaʻau faʻapipiʻi o le uʻamea uʻamea e suʻesuʻeina ma faʻatonuina e le spectrometer e maua ai le SAE Standard specification. O le u'amea u'amea e atomized ma liua i ni vaega lapotopoto ma mulimuli ane tineia ma faʻafefe i se faʻagasologa o le vevela e maua ai se oloa o le maaa tutusa ma microstructure, suʻeina e le tele e tusa ai ma le SAE Standard specification.

Junda uʻamea fana uʻamea ua vaevaeina i le fa, o se uʻamea tuʻufaʻatasia a le atunuu, o loʻo i ai chromium lafo uamea fana, fualaau mo uamea maualalo carbon, uamea stainless, e aofia ai le tulaga faaleatunuu lafo uamea fana e atoatoa e tusa ai ma tulaga manaomia tulaga faaleatunuu o anotusi elemene i le gaosiga, ma le elemene o le chromium lafo fana uamea, e faavae i luga o tulaga faaleatunuu o polo uamea, faaopoopo ferromanganese ferrochrome smelting faagasologa i le umi o le gaosiga o le faagasologa i totonu o le gaosiga o Owen; Low carbon u'amea fana fana faiga ma tulaga faaleatunuu fana uamea, ae o le mea mata e maualalo carbon sila, carbon anotusi e maualalo; Ua gaosia fana uamea e ala i le atomizing faiga faiga, mea mata o u'amea u'amea, 304, 430 uamea stainless ma isi.

O lenei ituaiga o fana e faia mo le fa'aoga i le fa'aosoina o fana ma faiga fa'apa'u i lalo o le mamafa e ala i le ea fa'amalosi. E masani ona faʻaaogaina i luga ole uʻamea e pei ole alumini, uʻamea zinc, uʻamea uʻamea, apamemea, apamemea, apamemea ...

Faʻatasi ai ma le lautele o faʻavasegaga, e faʻaaogaina mo le faʻamamaina, deburring, faʻapipiʻi, fana peening ma faiga faʻamaeʻaina lautele, i luga o ituaiga uma o vaega, e aunoa ma le faʻaleagaina o lona luga i pefu ferrous e faʻaleagaina ma suia le lanu o uʻamea togafitia. mo le faagasologa matua o maamora ma maamora.

Fa'aaogāga fa'apisinisi

Pa'u u'amea

u'amea fana faamamaina o le oneone lafo ma mu -i luga o le oneone o le lafo ina ia maua le tulaga mama lelei ma manaomia roughness, ina ia mafai ona manuia i le faagasologa mulimuli ane ma le ufiufi.

Tu'u u'amea fana mo sauniuniga luga o le ipu uamea

Tu'u u'amea fana fa'amama le pa'u oxide, 'ele ma isi le mama e ala i fana Blasting, ona fa'aogaina lea o le masini fa'amama po'o le ea fa'amama fa'amama e fa'amamā ai luga o oloa uamea.

U'amea fa'aoga mo masini Inisinia

u'amea u'amea fa'aaogaina mo le fa'amamaina o masini e mafai ona aveese lelei ai le 'ele, pa'u u'amea, ma le pa'u oxide, fa'ate'a ai le fa'amamafa o le uelo, ma fa'ateleina le malosi fa'amau i le va o le 'ele e aveese ai le ufiufi ma le u'amea, ma fa'apenaina ai le fa'aleleia atili o le lelei o le fa'ainisinia o vaega fa'ainisinia.

Lapo'a fana uamea mo le fa'amamaina o ipu uamea

Ina ia ausia le mama, susulu, matagofie burnish luga togafitiga o le ipu uamea stainless, e tatau ona filifili mea abrasive talafeagai e aveese le fua mai luga o le uamea taai malulu malulu.

E tusa ai ma togi eseese, e manaʻomia e le uʻamea uʻamea e filifili ni abrasives lautele eseese ma faʻatusatusa i le faagasologa. Fa'atusatusa i le fa'agasologa o vaila'au fa'aleaganu'u, e mafai ona fa'aititia ai le tau fa'amama ma ausia ai le gaosiga lanu meamata.

Fa'asalalauga fa'asalalau u'amea u'amea mo Pipeline anti-corrosion

O paipa uʻamea e manaʻomia togafitiga i luga o le eleele ina ia faʻamalosia ai le faʻafefeteina. E ala i le fana uʻamea, faʻapipiʻi faʻasalalau faʻasalalau, faʻamama ma aveese le oxide ma mea faʻapipiʻi e ausia ai le ele o loʻo talosagaina ma le loloto o le saito, e le gata o le faʻamamāina o luga ae faʻamalieina foi le pipii i le va o paipa uʻamea ma le ufiufi, ausia le lelei o le anti-corrosion.

Fa'amalosi le peening fana u'amea

O vaega u'amea o lo'o fa'agaoioia i le fa'asologa o le utaina ma fa'aoso i le fa'alavelave o le uila e mana'omia le fa'amalosiina o le faiga e fa'aleleia ai le ola vaivai.

La'u uamea fana Fa'aoga vaega

u'amea peening e masani ona faʻaaogaina i le faʻamalosia o le faʻaogaina o vaega taua e pei o le puna o le helical, laʻau laulaau, pa mimilo, mea faʻapipiʻi, vaega faʻasalalau, faʻapipiʻi, pusa cam, axle punou, tootoo ma isi. Pe a tulaueleele le vaalele, e tatau ona tatalia le mea e tulaueleele ai le aafiaga mata'utia e mana'omia ai le tui fana i taimi uma. E manaʻomia foʻi e apaʻau le faʻamalologa faʻamaʻi taimi.

Vaega Fa'atekinisi

| Poloketi | National Standards | Tulaga lelei | |

| Su'ega vaila'au% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Malosi | fana uamea | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Malosi | fana uamea | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | Tempered Martensite poʻo Troostite | Tempered Martensite Bainite Composite faalapotopotoga | |

| Fa'aaliga | Spherical O'o'o fasimea<10% vaega ta'e<15% | Spherical O'o'o fasimea<5% vaega ta'e<10% | |

| Ituaiga | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| afifiina | Tone ta'itasi i totonu o se Pallet eseese ma tone ta'itasi vaevae i pusa 25KG. | ||

| Tumau | 2500~2800 taimi | ||

| Malosi | 7.4g/cm3 | ||

| Diamita | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Talosaga | 1. Faʻamamāina o le pa: Faʻaaogaina mo le faʻamamāina o le faʻamaʻaina o le tuʻuina, mate-faʻamea, faʻamalosi; aveesea oneone o le lafo, ipu uamea, ituaiga H uamea, fausaga uamea. 2. Ave'esea ele: Ave'esea ele o le lafo, fa'ameamea, ipu uamea, H ituaiga sila, fausaga u'amea. 3. Peening fana: Peening o fana, vaega fa'afefeteina. 4. Fa'afana fana: Fa'a'a'a'a fana o fa'ailoga uamea, laupapa va'a, laupapa u'amea, mea uamea, fausaga u'amea. 5. Togafitiga muamua: Togafitiga muamua o luga, laupapa uʻamea, uʻamea faʻailoga, fausaga uʻamea, aʻo leʻi valiina poʻo le ufiufi. | ||

Tele Tufatufaina o Uamea fana

| SAE J444 Standard Steel fana | Screen Nu. | In | Tele lau | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| pasi uma | 6 | 0.132 | 3.35 | |||||||||||

| Pasi uma | 7 | 0.111 | 2.8 | |||||||||||

| 90% min | Pasi uma | 8 | 0.0937 | 2.36 | ||||||||||

| 97% min | 85% min | Pasi uma | Pasi uma | 10 | 0.0787 | 2 | ||||||||

| 97% min | 85% min | 5% maualuga | Pasi uma | 12 | 0.0661 | 1.7 | ||||||||

| 97% min | 85% min | 5% maualuga | Pasi uma | 14 | 0.0555 | 1.4 | ||||||||

| 97% min | 85% min | 5% maualuga | Pasi uma | 16 | 0.0469 | 1.18 | ||||||||

| 96% min | 85% min | 5% maualuga | Pasi uma | 18 | 0.0394 | 1 | ||||||||

| 96% min | 85% min | 10% maualuga | Pasi uma | 20 | 0.0331 | 0.85 | ||||||||

| 96% min | 85% min | 10% maualuga | 25 | 0.028 | 0.71 | |||||||||

| 96% min | 85% min | Pasi uma | 30 | 0.023 | 0.6 | |||||||||

| 97% min | 10% maualuga | 35 | 0.0197 | 0.5 | ||||||||||

| 85% min | Pasi uma | 40 | 0.0165 | 0.425 | ||||||||||

| 97% min | 10% maualuga | 45 | 0.0138 | 0.355 | ||||||||||

| 85% min | 50 | 0.0117 | 0.3 | |||||||||||

| 90% min | 85% min | 80 | 0.007 | 0.18 | ||||||||||

| 90% min | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Laasaga o gaosiga

Mea mata

Fausia

Fa'amago

Su'ega

Filifiliga

Fa'aitaita

Su'ega

afifi

Vaega o oloa